Steam Generation Africa (Pty) Ltd together with our world renown partners, design, manufacture, install, maintain, and supply spare parts for coal, oil, gas, biomass, heat recovery and immersed element type electric steam boilers. The range of steam boilers across our offering is from 50Kg/hour to 40 000Kg/hour.

Cochran our main partner and of which we are their exclusive distributor for Southern Africa offers the range and flexibility to deliver solutions that match the application, backed-up by a complete package of technical advice and design and manufacture.

Cut fuel consumption, reduce emissions and save money

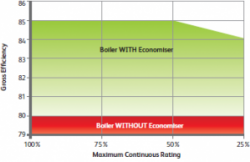

The thermal efficiency of a boiler is dependent on the heat lost in the exhaust gases. Wastage is directly related to the temperature of the boiler water, since the exhaust temperature cannot be less than that of the boiler water.

Cochran Economisers reduce the temperature of exhaust gas y transferring its heat into the feed water before it enters the boiler, thereby raising its temperature and increasing the overall thermal efficiency. Improving thermal efficiency cuts fuel use, resulting in significant cost savings and reduced emissions. In fact, the capital cost of fitting a Cochran Economiser is often recovered within a pay back period of 12 months.

Cochran’s Economisers can be fitted to all makes and Models of oil and gas fired boilers, new or old. However, in the case of oil-fired boilers, potential fuel and efficiency savings are limited b the need to avoid acid ‘dewpont’ temperature conditions within the chimney. The Company can factory fit Economisers to every new Cochran boiler pre-despatch and can retrofit units to the full spectrum of existing boilers.

The principal of Economisers

Economisers for both new and existing installations

Cochran Economisers can be supplied to fit every make and model of boiler, new or old. Each unit is supplied complete with a Safety Valve, Vent Valve, Drain Valve, Outlet Water Temperature Gauge, and n Auto-Bleed Valve.

The Auto-Bleed Valve is supplied with an actuator switch, which is fitted to the boiler feed Water Regulating Valve. At low operating loads, or whenever the regulating valve approaches its closed position, the Bleed Valve automatically operates to ensure a flow of water through the Economiser at all times. This prevents overheating and ‘steaming’ within the unit that can result in ‘vapour locking’. The outlet from the Auto-Bleed Valve is piped back to the boiler feed tank.

Whether boiler-mounted or standalone, every Cochran-supplied Economiser also features aluminium cladding and external insulation to maximise efficiency.

Ideally, Economiser units should be formatted to provide a vertical gas flow. However, if utilised within a horizontal gas flow, then additional vent and drain connections are fitted.

Boiler-mounted Economiser fitted to the rear of the Boiler

Standalone Economiser located at the rear of the Boiler